Specialist Welding Inspection Service for Safety And Security Conformity

Specialist Welding Inspection Service for Safety And Security Conformity

Blog Article

Understanding the Numerous Kinds of Welding Techniques and Solutions Available

Introduction of Welding Methods

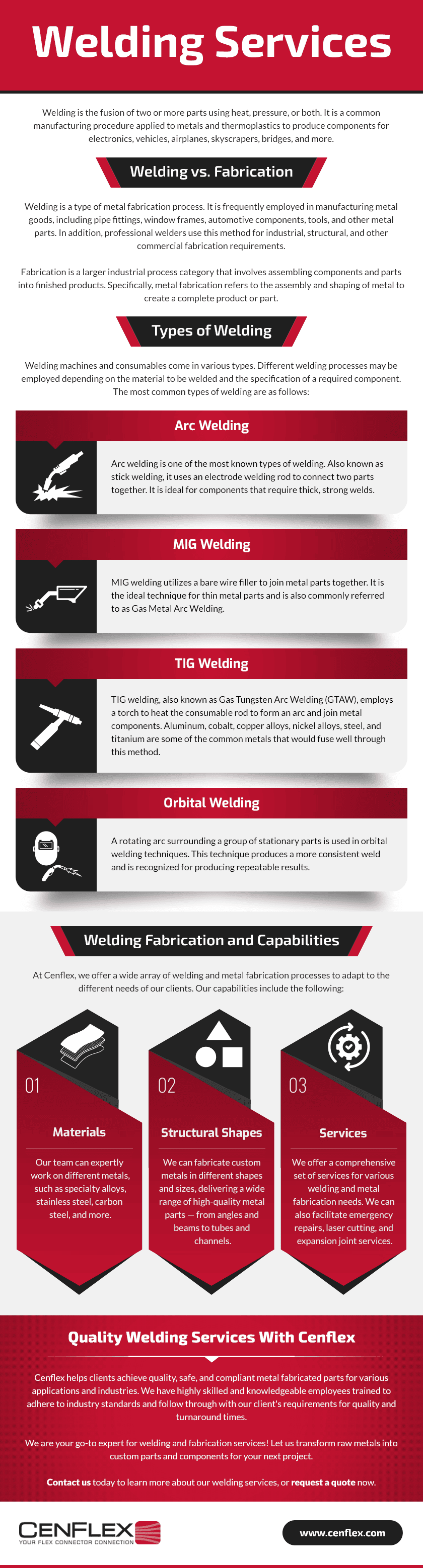

Welding methods include a varied series of techniques made use of to join products with each other completely. One common approach is arc welding, which includes creating an electric arc in between an electrode and the base material to thaw and fuse them with each other. This technique is functional and can be used with various steels, making it one of one of the most extensively made use of welding procedures.

Additionally, TIG welding, or Gas Tungsten Arc Welding (GTAW), is a accurate and clean welding method that utilizes a non-consumable tungsten electrode to create the weld. TIG welding is commonly utilized for thinner products and offers exceptional control over the welding process. In general, recognizing these various welding methods is necessary for choosing one of the most suitable method for various tasks.

Typically Made Use Of Welding Approaches

A variety of commonly utilized approaches are employed in the field of welding to properly sign up with products together. One of the most widely utilized techniques is Gas Steel Arc Welding (GMAW), likewise called MIG welding. This approach uses a cord electrode that is fed via a welding gun, in addition to a shielding gas to safeguard the weld from contaminants airborne. Another usual approach is Secured Steel Arc Welding (SMAW), or stick welding, which utilizes a flux-coated electrode to produce the weld. Tungsten Inert Gas (TIG) welding is preferred for its precision and adaptability, using a non-consumable tungsten electrode to create the weld. Flux-Cored Arc Welding (FCAW) is generally utilized in commercial setups as a result of its high welding rate and transportability. In Addition, Immersed Arc Welding (SAW) is ideal for creating deep welds on thick materials. These generally made use of welding techniques cater to various requirements and products, supplying alternatives for various welding applications.

Advanced Welding Provider

Building upon the structure of typically made use of welding techniques, the realm of sophisticated welding services encompasses innovative techniques and innovations that push the limits of precision and effectiveness in product joining processes. Advanced welding services commonly include specialized methods such as laser welding, electron beam welding, and rubbing mix welding. Laser welding uses an extremely focused beam of light of light to exactly sign up with steels with marginal heat-affected zones, making it ideal for fragile or complex components. Electron beam welding, on the other hand, utilizes a high-velocity electron beam of light to create deep weld penetrations in materials like aerospace alloys or dissimilar steels. Rubbing mix welding, a solid-state joining process, allows the welding of products that are challenging to fuse using typical approaches, like aluminum and copper. These innovative techniques provide improved control over the welding procedure, resulting in stronger, a lot more sturdy welds with decreased distortion and enhanced total quality.

Specialized Welding Techniques

An additional specialized welding method is laser beam of light welding, where a highly concentrated beam is utilized to join steels with marginal heat-affected zones and distortion. This technique is typically utilized in industries requiring high precision and sanitation, such as electronics and medical tool manufacturing. Furthermore, eruptive welding is pop over to this web-site a distinct strategy that utilizes regulated explosives to bond dissimilar metals together, developing trustworthy and strong joints. These specialized welding techniques display the diversity and development existing in the area of welding, providing services for a vast array of industrial applications.

Choosing the Right Welding Refine

Picking the ideal welding procedure is extremely important in achieving optimal outcomes in metal fabrication and signing up with operations. With numerous welding methods offered, it is essential to think about aspects such as the sort of metal, density, joint layout, and wanted end result when choosing the appropriate welding procedure - Welding Inspection Service. Among the typical welding methods are Gas Metal Arc Welding (GMAW), Protected Steel Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) GMAW, additionally recognized as MIG welding, appropriates for welding thin to thick metals and is functional in different positions. On the various other hand, SMAW, or stick welding, is a trusted method for outdoor and field welding as a result of its portability and simpleness. GTAW, or TIG welding, is perfect for welding Continued thin products and offers accurate and premium welds. FCAW is chosen for welding thick materials and is known for its high welding speeds. Understanding the qualities of each welding procedure is important in choosing the most appropriate technique for a particular welding job.

Final Thought

To conclude, understanding the various sorts of welding methods and services available is vital for choosing the right method for a details task. By understanding the typically made use of welding methods, advanced welding services, and specialized strategies, people can make enlightened choices to guarantee the success of their welding tasks. It is essential to think about factors such as materials, job requirements, and budget plan when picking one of the most suitable welding procedure.

From typical techniques like stick welding to look at this website innovative processes such as laser welding, the world of welding uses a plethora of choices for signing up with metals together.In addition, TIG welding, or Gas Tungsten Arc Welding (GTAW), is a tidy and specific welding method that utilizes a non-consumable tungsten electrode to develop the weld. Advanced welding services often include specialized methods such as laser welding, electron light beam welding, and rubbing stir welding. Amongst the typical welding approaches are Gas Steel Arc Welding (GMAW), Shielded Steel Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) By being aware of the generally used welding methods, advanced welding services, and specialized techniques, people can make enlightened decisions to ensure the success of their welding jobs.

Report this page